The concept

behind neon signs was first conceived in 1675, when the French astronomer Jean

Picard observed a faint glow in a mercury barometer tube. When the tube was

shaken a glow called barometric light occurred, but the cause of the light (static

electricity) was not then understood.

Even though barometric light was not yet understood, it was investigated. When

the principles of electricity were discovered, scientists moved forward towards

the invention of various forms of lighting. By 1855, there was the geissler

tube named after Heinrich Geissler, a German glassblower. Gas in the tube was

placed under low pressure and electrical voltage was applied, the result was

that the gas glowed. After electrical generators were invented, many people

experimented with applying electric power to tubes of gas. Several electric

discharge lamps or vapor lamps were invented from 1900 onwards in Europe and

the United States. Simply defined the electric discharge lamp is a lighting

device consisting of a transparent container within which a gas is energized

by an applied voltage, and thereby made to glow.

Before there were neon signs in America, there were commercial sign tubes that

used a carbon dioxide fill. The carbon dioxide signs were made by a man called

Moore. Neon gas was discovered by William Ramsey and M. W. Travers in 1898 in

London. Neon is a rare gaseous element present in the atmosphere to the extent

of 1 part in 65,000 of air. It is obtained by liquefaction of air and separated

from the other gases by fractional distillation.

|

The French engineer, chemist, and inventor Georges Claude was the first to apply

an electrical discharge to a sealed tube of neon gas to create a lamp. The word

neon comes from the Greek "neos," meaning "the new gas." On December 11, 1910,

Georges Claude produced the first neon light in France, which he displayed at

the Grand Palais in Paris. His invention was patented in 1915, and in 1923 Georges

Claude and his French company Claude Neon, introduced neon gas signs to the

United States, by selling two to a Packard car dealership in Los Angeles. Earle

C. Anthony purchased the two signs reading "Packard" for $24,000. Neon lighting

quickly became a popular fixture in outdoor advertising. Visible even in daylight,

people would stop and stare at the first neon signs dubbed "liquid fire." Nothing

catches the eye like neon, and it has been the most effective medium for signs

all over the world ever since.

Toward the end of the 1950's, as many of the old neon sign craftsmen were retiring,

the neon industry could not keep up with demand, and other forms of signage

became popular using new plastics, and fluorescent bulbs. While the initial

cost of these newer types of electrical signs was cheap, fluorescent bulb life

is very short which greatly increases maintenance costs over the life of a sign.

Because neon tubes last for many years, are so much brighter, create more eye

appeal, and can be bent to any shape, the demand stayed high. To fill this demand,

new craftspeople were trained and neon rose again to become the most effective

medium for electric signs.

|

Today the manufacturing process remains basically the same. Each tube is hand

made, heated to a pliable state by fire with a gas torch, bent to shape, blown

out, and then laid on a heatproof pattern for final adjustments before it cools

and becomes hard again. The mechanical equipment required purifying and process

the tube into a vacuum tube has improved greatly, thus improving the quality

and life of modern neon signs.

Since neon was first used in signs, it has captured the imagination of everyone

who sees it. Neon grabs your attention and holds on until the message has been

effectively delivered. Neon is commonly used as a great accent to other type

of signs; for instance, it is often used to illuminate the interiors of channel

letters and other closed-face signage.

How does a Neon

Sign work?

Hollow glass tubes used to make neon lamps come in 4, 5 and 8-ft lengths. To

shape the tubes, the glass is heated by lit gas and forced air. Several compositions

of glass are used depending on the country and supplier. What is called 'Soft'

glass has compositions including lead glass, soda-lime glass, and barium glass.

"Hard" glass in the borosilicate family is also used. Depending on the glass

composition, the working range of glass is from 1600' F to over 2200'F. The

temperature of the air-gas flame depending on the fuel and ratio, is approximately

3000'F using propane gas.

The tubes are scored (partial cut) while cold with a file and then snapped apart

while hot. Then the artisan creates the angle and curve combinations. When the

tubing is finished, the tube most is processed. This process varies depending

on country; the procedure is called "bombarding" in North America. The tube

is partial evacuated of air.

Next, it is short circuited with high voltage current until the tube reaches

a temperature of 550 F. Then the tube is evacuated again until it reaches a

vacuum of 10-3 torr. Argon or neon is back filled to a specific pressure depending

on the diameter of the tube and sealed off. In the case of an argon-filled tube,

additional steps are taken for the injection of mercury; typically, 10-40ul

depending on tube length and climate it is to operate in.

|

Red is the color neon gas produces, neon gas glows with its characteristic red

light even at atmospheric pressure. There are now more than 150 colors possible;

almost every color other than red is produced using argon, mercury and phosphor.

Neon tubes actually refer to all positive-column discharge lamps, regardless

of the gas filling. The colors in order of discovery were blue (Mercury), white

(Co2), gold (Helium), red (Neon), and then different colors from phosphor-coated

tubes. The mercury spectrum is rich in ultraviolet light which in turn excites

a phosphor coating on the inside of the tube to glow. Phosphors are available

in most any pastel colors.

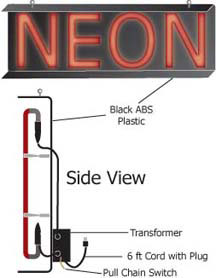

Neon lights operate on relatively high voltage, but very low amperage (high

pressure, but very low volume). Imagine a garden hose with only a trickle of

water. Put your thumb over the end, and it comes out with more force, but you

use much less water. Just like water pressure, a transformer is needed to increase

the electrical pressure from your wall outlet, to the required current to make

the gas inside the tube "glow". Even though neon operates at a higher voltage,

the transformer (included with your sign) does all the work, thus keeping your

electrical cost low.

Common Coloring

Methods

| Insert Inert Gas |

As mentioned above, people use neon and argon/mercury. Neon

gives off a reddish-orange color, while argon/mercury is a light blue. |

| Fluorescent Powders |

Many neon tubes are coated on the inside with fluorescent

powders that filter out different colors from the light spectrum. In combination

with the different gasses, an even greater number of colors are achieved.

For instance, a green tube, filled with argon/mercury (blue gas) will

light up green. Fill the same tube with neon (red gas) and it lights up

orange. Likewise a blue tube, filled with blue gas will light up blue,

and the same blue tube filled with red gas will light up pink. |

| Colored Glass |

The use of colored glass is an old world method, which achieves

the most vivid colors (reddest reds, deepest blues, etc.), but they are

not as bright as other neon. They are also more costly, so are not used

as widely for signs as they once were. However, for neon artwork, they

are unparalleled in beauty. |

Want to know more about Neon Signs? Please contact the

Sign

Shops listed in Allprintings.com.